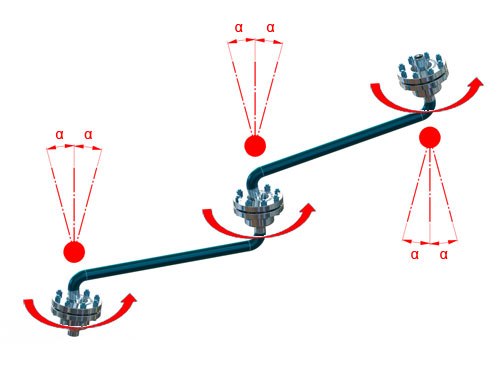

ROTOFLUID ball joints are used when there is a need for a movable pipe-connection system between two equipment parts. Ball joints provide reliable and safe operation when transferring the product under extreme application parameters. In addition to loads caused by internal pressure; ROTOFLUID ball joints absorb external, radial, axial and bending forces. The maximum permissible load of a joint depends on many operational factors.

Temperature change, ground sinkage, earthquake and other factors cause pipelines to expand, contradict, shifting of axes, to bend, to twist. Ball joints can absorb these displacements.

ROTOFLUID ball joints are used in petroleum refineries, oil production, chemical process plants, industrial power plants, transportation terminals and in various sectors.

ROTOFLUID ball joints are used in

-Flexible piping systems

-Stationary piping to moving equipment

-Moving piping to stationary equipment

-Storage tank connections

-Long piping systems where temperature causes linear thermal expansion/contradiction

BALL FEATURES

-Ball joints reduce the number and weight of anchors and guides in a piping system

-Ball joints can withstand heavy shock and vibration

-Ball joints are designed for low maintenance and do not need service continuously

-Ball joints both rotate and flex angularly

-Ball joints flex under very low forces causes lower end thrust

Temperature change, ground sinkage, earthquake and other factors cause pipelines to expand, contradict, shifting of axes, to bend, to twist. Ball joints can absorb these displacements.

ROTOFLUID ball joints are used in petroleum refineries, oil production, chemical process plants, industrial power plants, transportation terminals and in various sectors.

ROTOFLUID ball joints are used in

-Flexible piping systems

-Stationary piping to moving equipment

-Moving piping to stationary equipment

-Storage tank connections

-Long piping systems where temperature causes linear thermal expansion/contradiction

BALL FEATURES

-Ball joints reduce the number and weight of anchors and guides in a piping system

-Ball joints can withstand heavy shock and vibration

-Ball joints are designed for low maintenance and do not need service continuously

-Ball joints both rotate and flex angularly

-Ball joints flex under very low forces causes lower end thrust

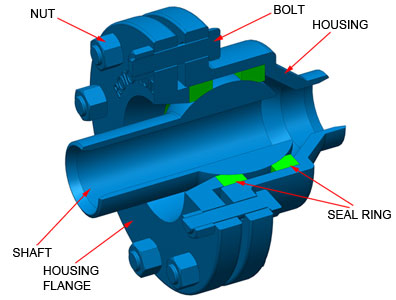

SEALS

-Sealing surfaces are plated special corrosion resistance material for longer service life

-Many different seal alternatives according to application parameters

SEAL MATERIALS

- Teflon

- Graphite Filled Teflon

- Bronze Filled Teflon

- Glass Filled Teflon

- Mineral Compound with Injectable Graphite Sealant

- Aluminium Bronze with Injectable Graphite Sealant

- Ductile iron with Injectable Graphite Sealant

MATERIALS

- ROTOFLUID swivel joints are made of

- 42CrMo4 (1.7225)

- St52-3 (1.0570)

- AISI304, AIS316, AISI316 TI (1.4571)

- Aluminium

- Brass

- Special Materials upon request

-Sealing surfaces are plated special corrosion resistance material for longer service life

-Many different seal alternatives according to application parameters

SEAL MATERIALS

- Teflon

- Graphite Filled Teflon

- Bronze Filled Teflon

- Glass Filled Teflon

- Mineral Compound with Injectable Graphite Sealant

- Aluminium Bronze with Injectable Graphite Sealant

- Ductile iron with Injectable Graphite Sealant

MATERIALS

- ROTOFLUID swivel joints are made of

- 42CrMo4 (1.7225)

- St52-3 (1.0570)

- AISI304, AIS316, AISI316 TI (1.4571)

- Aluminium

- Brass

- Special Materials upon request