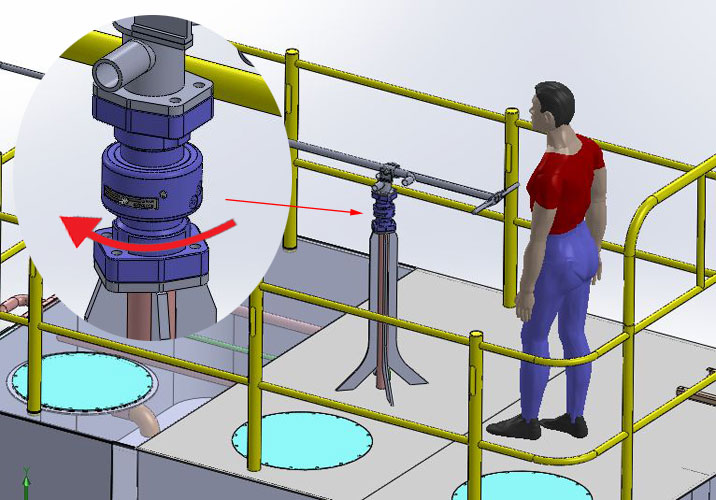

ROTOFLUID swivel joints are used when there is a need for a movable pipe connection system between two equipment parts. Swivel joints provide reliable and safe operation when transferring the product under extreme application parameters. In addition to loads caused by internal pressure; ROTOFLUID swivel joints absorb external, radial, axial and bending forces. The maximum load of a joint depends on many operational factors.

ROTOFLUID swivel joints are used in ;

*Loading arms

*Flexible piping systems

*Hose reels

*Floating roof drains

*Floating suction systems

ROTOFLUID swivel joints are used in ;

*Loading arms

*Flexible piping systems

*Hose reels

*Floating roof drains

*Floating suction systems

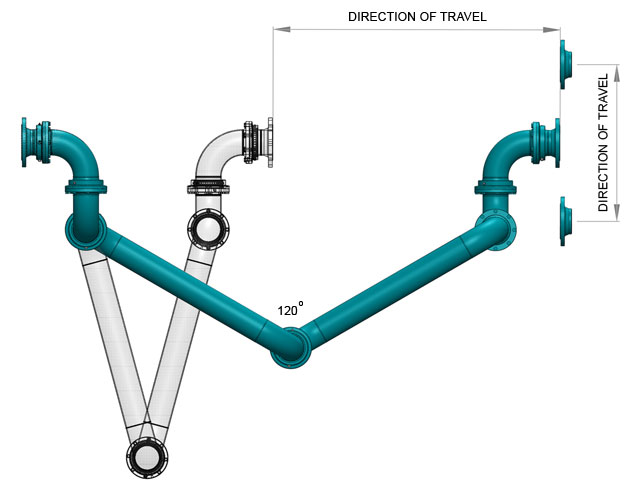

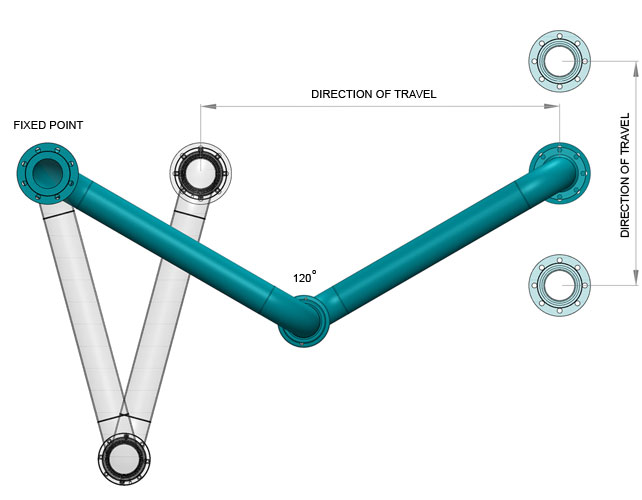

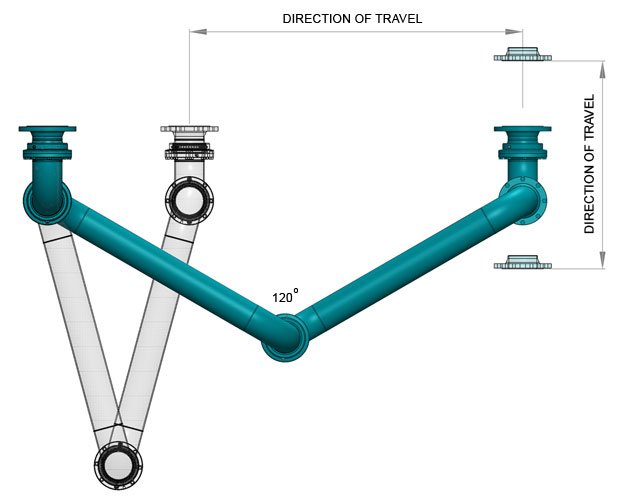

Swivel joint systems are composed of combinations of swivel joints and pipes. It is possible to achieve desired motions of two points relative to each other by selection of appropriate swivel joints.

For applications where hoses are not considered suitable, the use of swivel joints and pipes is an ideal alternative solution. Rotary connections are developed and manufactured according to customer defined specifications.

For applications where hoses are not considered suitable, the use of swivel joints and pipes is an ideal alternative solution. Rotary connections are developed and manufactured according to customer defined specifications.

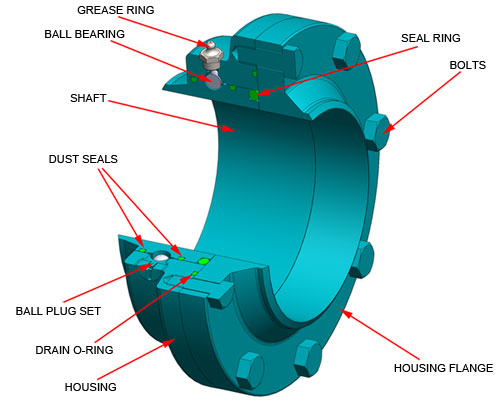

SWIVEL JOINT FEATURES

SEALS

-Sealing surfaces are plated with special corrosion resistance material for longer service life

-Many different seal alternatives according to application parameters

General combinations

- O-ring seal (Viton, NBR, PTFE, etc.)

- Spring energized lip seal (PTFE, etc.)

- H Block seal (PTFE, etc.)

- Packing seal with extrusion ring (NBR, EPDM, etc.)

OPTIONS

*Swivel joints with internal scraper for very dirty medium that contains abrasives

*Swivel joints with external sealing

*Swivel joints with external rod wiper

SEALS

-Sealing surfaces are plated with special corrosion resistance material for longer service life

-Many different seal alternatives according to application parameters

General combinations

- O-ring seal (Viton, NBR, PTFE, etc.)

- Spring energized lip seal (PTFE, etc.)

- H Block seal (PTFE, etc.)

- Packing seal with extrusion ring (NBR, EPDM, etc.)

OPTIONS

*Swivel joints with internal scraper for very dirty medium that contains abrasives

*Swivel joints with external sealing

*Swivel joints with external rod wiper

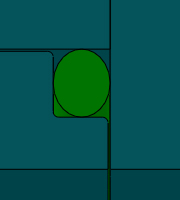

O-RING

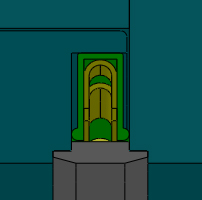

SPRING ENERGIZED LIP SEAL

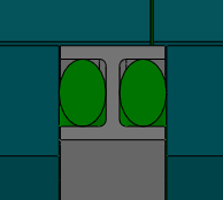

H BLOCK SEAL

PACKING SEAL WITH EXTRUSION RING

BALL BEARINGS & RACES

*3 and 4 piece design allows seals to be changed without removing ball bearings

*Widely spaced ball bearings

*Ball races are manufactured with close tolerances

*Deep hardened ball races offer higher load capacity

*Inner and outer dust seals/o-rings protect bearing chamber and hold lubrication in chamber

MATERIALS

ROTOFLUID swivel joints are made of

*42CrMo4 (1.7225)

*St52-3 (1.0570)

*AISI304, AIS316, AISI316 TI (1.4571)

*Aluminium

*Brass

*Special Materials upon request

*3 and 4 piece design allows seals to be changed without removing ball bearings

*Widely spaced ball bearings

*Ball races are manufactured with close tolerances

*Deep hardened ball races offer higher load capacity

*Inner and outer dust seals/o-rings protect bearing chamber and hold lubrication in chamber

MATERIALS

ROTOFLUID swivel joints are made of

*42CrMo4 (1.7225)

*St52-3 (1.0570)

*AISI304, AIS316, AISI316 TI (1.4571)

*Aluminium

*Brass

*Special Materials upon request

LUBRICATION

*All swivels that do not have a grease ring are lubricated before shipment and do not need lubrication before start-up.

*All swivels with grease rings must be lubricated periodically.

*To prevent over greasing, all swivel joints ae equipped with grease relief fitting.

SPECIALS

*Heated swivel joints

*High-pressure swivel joints (up to 1200bar)

*High temperature swivel joints (UP TO 700⁰C)

*Low temperature swivel joints (down to -90⁰C)

*Special designs for submerged operation

*All swivels that do not have a grease ring are lubricated before shipment and do not need lubrication before start-up.

*All swivels with grease rings must be lubricated periodically.

*To prevent over greasing, all swivel joints ae equipped with grease relief fitting.

SPECIALS

*Heated swivel joints

*High-pressure swivel joints (up to 1200bar)

*High temperature swivel joints (UP TO 700⁰C)

*Low temperature swivel joints (down to -90⁰C)

*Special designs for submerged operation