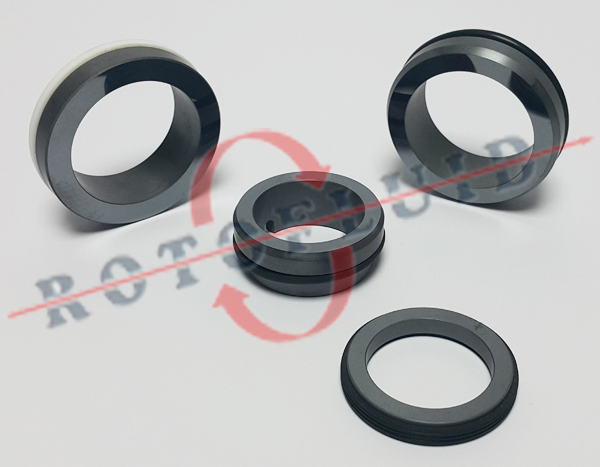

TYPE 1: ALPHA SINTERED SIC TYPE 2: REACTION BONDED SIC TYPE 3: UNIQUE CHEMICAL PROCESSING TYPE 4: SINTERED CONTAIN GRAPHITE SILICON CARBIDE TYPE 5: POROUS SILICON CARBIDE

Purity > %98

Relative Density > %96

High Wear Resistance

High Corrosion Resistance

High Heat Resistance

High Thermal Conductivity

High Thermal Shock Resistance

Electric Discharge Proscessable Conductivity

High Thermal Shock Resistance

High Self Lubricity

SMALL FRICTION OF COEFFICIENT

GOOD SELF LUBRICITY

EXCELLENT ANTI-FRICTION PROPERTIES

|

TECHNICAL PROPERTY DATA SHEET |

|||||

|

TYPE 1 |

TYPE 2 |

TYPE 3 |

TYPE 4 |

TYPE 5 |

|

|

Process |

Alpha Sintered SiC |

Reaction Bonded SiC |

Unique Chemical Processing |

Sintered Carbide Contain Graphite |

Porous Silicon Carbide |

|

Content (wt%) |

SiC≥98% |

SIC-12%Si |

SiC-30%~40%C |

||

|

Gravity |

3.12 |

3.05 |

2.3 |

>3.02 |

2.9-3.04 |

|

Hardness |

Hs120 |

Hs110 |

Hs90 |

||

|

Hv2400 |

Hv1700 |

Hv2250 |

Hv2400 |

||

|

Bending Strength |

490 |

392 |

127 |

410 |

260 |

|

Flexural Strength (Gpa) |

360 |

350 |

25 |

320 |

350 |

|

Poisson’s Ratio |

0.20 |

0.20 |

0.20 |

0.21 |

0.2 |

|

Fracture Toughness (MN/M) |

2.4 |

2.8 |

2.2 |

2.4 |

|

|

Thermal Conductivity (W/m.K) |

147 |

151 |

38 |

135 |

110 |

|

Thermal Expansion Coeff.(I/℃) |

3.5X10-6 |

3.1X10-6 |

3.2X10-6 |

3.4X10-6 |

3.6X10-6 |

|

(RT~400℃) |

(RT~400℃) |

(RT~400℃) |

(RT~400℃) |

(RT~400℃) |

|

|

Heat Resistance(in the air) |

1600℃ |

1400℃ |

400℃ |

1600℃ |

1600℃ |

|

Thermal Shock Resistance △TMM |

200℃ |

250℃ |

400℃ |

200℃ |

|